Explore

Space

Enabling your mission, from microgravity research to satellite deployment and commercial activities.

Expanding Frontiers

Starlab is unleashing the next generation of commercial space destinations.

Starlab

Unleashing the next generation of space destinations.

Starlab, a US-led joint venture between Voyager Space and Airbus, will serve global space agencies and companies while ensuring continued human presence in low-Earth orbit and the transition of microgravity research into the new commercial era.

Voyager

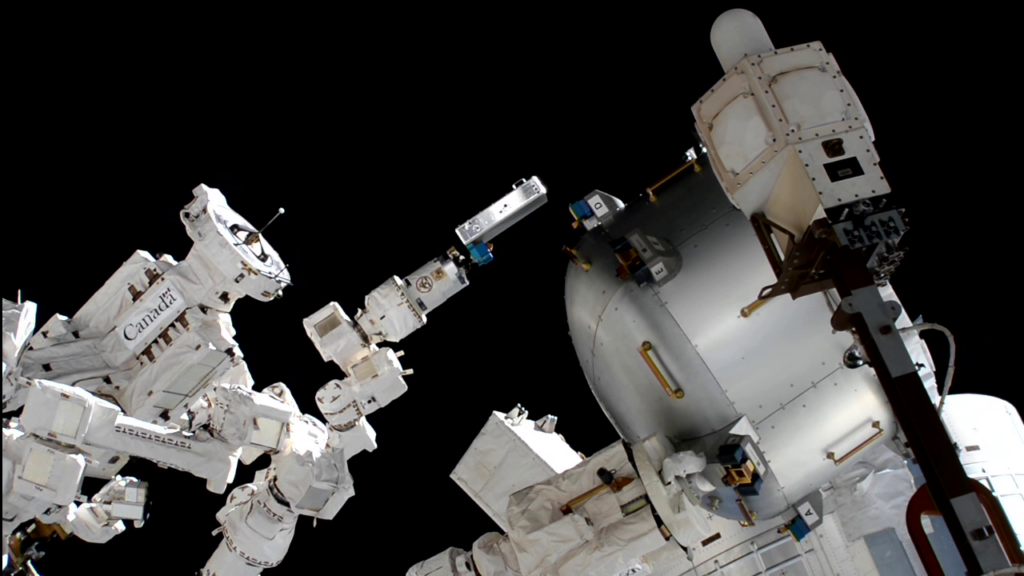

Airlock

Airlocks, critical infrastructure for all space stations, facilitate movement between the internal station environment and the vacuum of space. From hosted payloads to robotics research and satellite deployment, learn how Bishop can advance your mission.

Our spacecraft technologies have long-standing heritage, enabling LEO, GEO and Cislunar missions since 2006 with a failure-free cumulative track record. Our solutions include rad-hardened laser and RF communications systems, electro-optical and digital systems, star trackers, space situational awareness-capable space cameras, image processors, command and data handling systems, and solutions for in-space servicing and assembly.

Propulsion

Our controllable solid propulsion technologies make solids perform like liquids. This technology allows for the in-flight modulation of thrust for solid fuel boosters, enabling a dramatic improvement in accuracy for both subsonic and hypersonic systems.

& Tech

We are the leading provider of commercial research opportunities in low-Earth orbit. Whether you are designing your own plug-and-play payload leveraging our standardized hardware, or want our team to build a custom research platform for you – we are here to help.

Intelligence

We offer software and technologies that provide space-to-Earth and space-to-space visualization in support of Intelligence, Surveillance, and Reconnaissance (ISR) applications.

& Medicine

Our technologies help solve the medical and physiological problems of spaceflight and off-world surface exploration. We deliver a broad range of novel, non-invasive, and versatile instrumentation and hardware tailored for space mission-unique requirements.

Forging

the Future.

We are Voyager Space, a leading space company dedicated to bettering humanity’s future through bold exploration, cutting-edge technologies, and an unwavering drive to protect our planet and our people.

It Takes a Planet to

Explore the Universe

We’re committed to advancing humanity by driving space norms, empowering youth, and valuing sustainability from Earth to orbit, aiming for a prosperous future with a lasting, positive impact.